The UK manufacturing industry employees millions of workers each year. While many of these workplaces offer a safe work environment, others do not. In fact, there are an average of 22 worker deaths per year in this sector. The reality is that the manufacturing environments are inherently dangerous. However, there are several simple workplace safety measures that both workers and employers can adhere to avoid the key dangers that manufacturing workers may face. We’ve outlined some Simple tips for Safety in the manufacturing industry.

Slips, trips and falls

Slips, trips and falls are not exclusive to the manufacturing sector. This type of hazard is responsible for up to 40% of workplace injuries. Aside from the incalculable cost to the individual (lost income, pain suffered, reduced quality of life, etc.), the HSE report that slips, trips and falls cost employers over £500m per year.

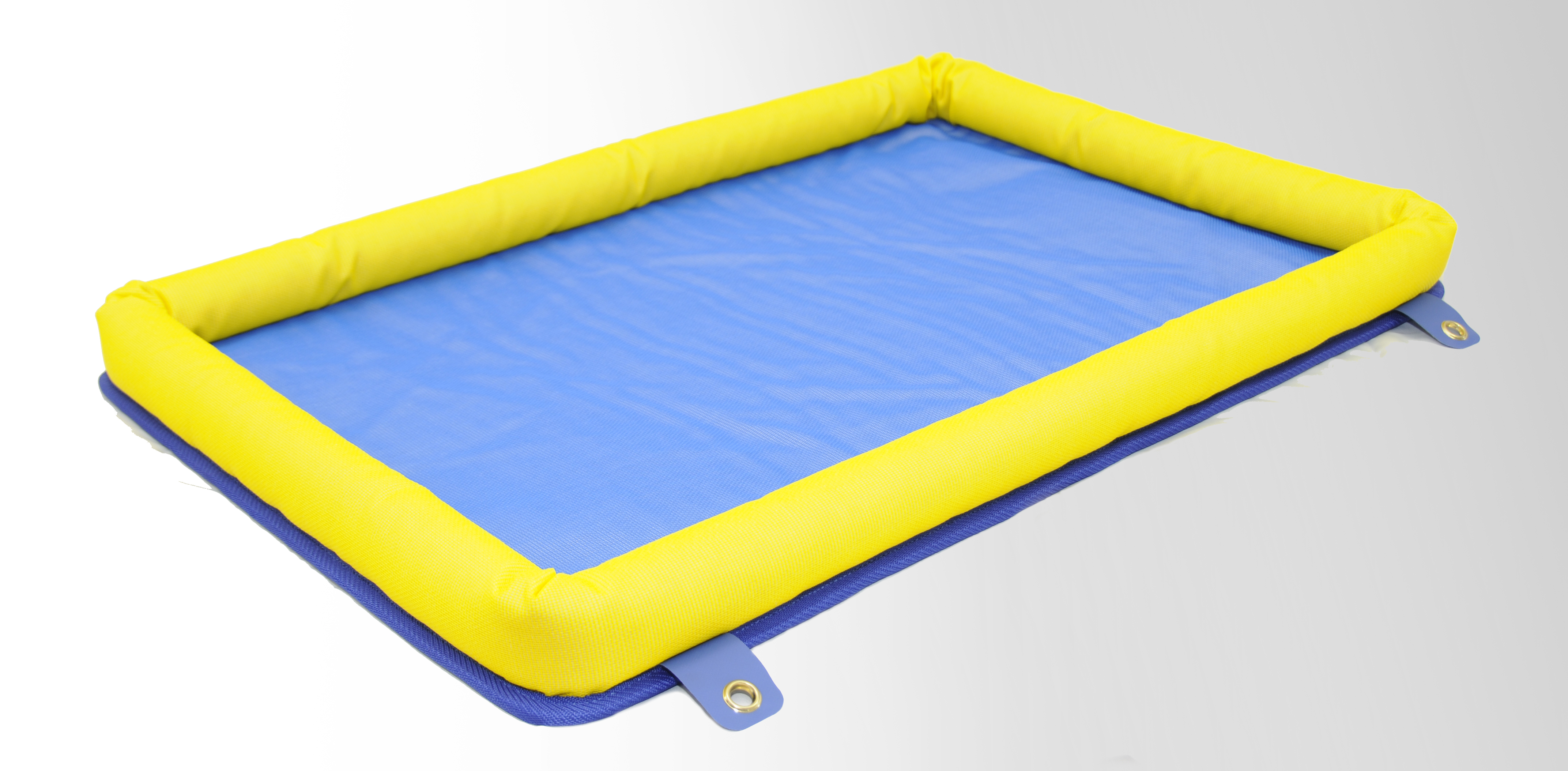

For factories and industrial warehouses, there is safety law and various legal requirements and precautions needed to be taken. For example, if 200 litres or more of oil is stored aboveground, it must be held in sufficient bunded containers. Of which the bund must be able to hold 110% of the capacity in case of any overspills.

Simple tips for Safety in the manufacturing industry

To reduce the risks of slips, trips and falls in a manufacturing setting, manufacturing processes must be in place to prevent potential hazards. It is important to know that it is not just wet processes and spills that can cause slips, dry material accumulation can also cause floors to be slippery.

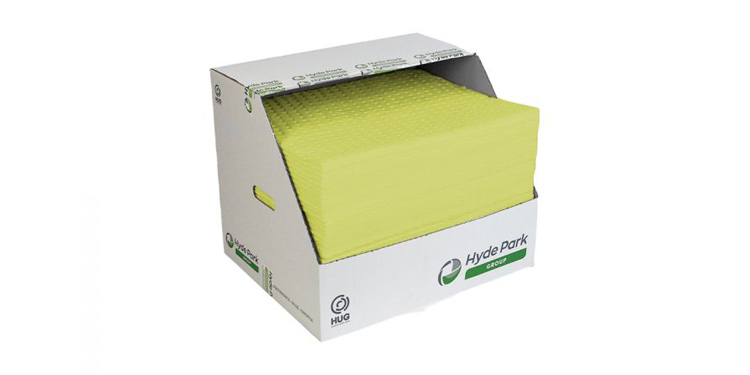

Manufacturing businesses are likely to carry out work that involves hazardous substances or produces hazardous wasteHazardous substances, contaminants and liquids can be kept from becoming hazardous through risk assessments and good housekeeping.

8 Tips to avoid slips:

- Prepare for spills by installing anti-slip flooring, raised grates or absorbent matting.

- Have the right processes and safety procedures in place for spill response.

- Report any spills and leaks.

- Maintain cleaning, safety equipment and spill kit equipment so it remains effective.

- Ensure spills and leaks are cleaned up immediately with the right spill response equipment.

- Ensure wet floor signs and warning signs are used when needed.

- Use drip trays in spill and leak prone areas.

- Wear appropriate PPE.

8 Tips to avoid trips:

- Keep passageways, aisles, stairs, exits and delivery areas clear.

- Ensure the work area is well lit.

- Clear up clutter.

- Avoid untidy cables.

- Report damaged floors, use warning signs to highlight hazards.

- Keep equipment in suitable storage places.

- Ensue employees use proper manual handling techniques .

- Wear appropriate PPE.

5 Tips to avoid falls:

- Understand the requirements of the work at height regulations.

- Plan, organise and supervise work activities.

- Inspect and maintain safety equipment.

- Wear appropriate PPE.

- Report any safety hazards, like equipment defects.

Some of our top products for the manufacturing industry are:

Machine Injuries

It has been reported that machine and heavy machinery related injuries account for 19% of manufacturing fatalities and 13% of major accidents and 11% of minor injuries in the UK.

4 Tips to avoid machine related injuries:

- Avoid interfering with moving machinery

- Only use machinery for which you are properly trained

- Use the right machine guards

- Wear the right safety gear and PPE

Falling Objects

HSE’s Riddor Report shows that dropped objects still rank in the top 3 for workplace fatalities in the UK. High shelving and poor storage solutions can pose health and safety hazards for workers. Pallets, shelving and general purpose storage are great for clearing floor space to prevent slips trips and falls. However they can pose their own hazards.

Tips to avoid falling objects hazards:

- Require hard hats and other required PPE for every person in areas at risk for falling objects.

- Store materials securely to avoid them sliding, falling or collapsing.

- Use toe boards or guardrails on scaffolds to prevent objects from falling.

- Report faulty equipment.

- Develop an emergency procedure for falling object hazards.

The manufacturing industry is filled with potential health and safety issues. Therefore it is important to know the ways in which you and your employees can effectively mitigate danger by improving your health and safety measures.

If you are looking for ways to improve your health and safety measures for spill control in your manufacturing business, get in touch with our spill control experts.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers