What is a bund?

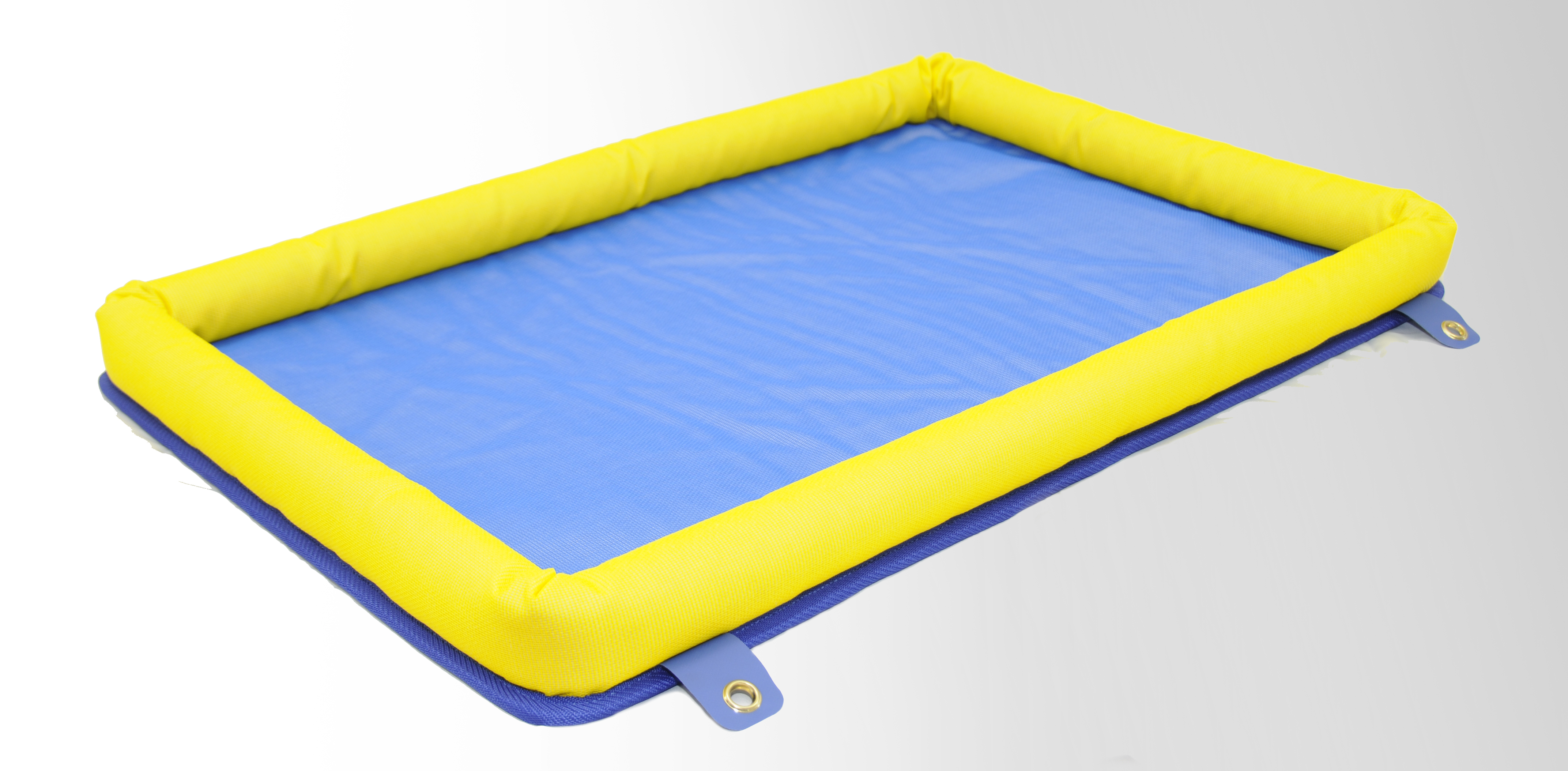

A bund is a secondary containment system that is used to catch leaks or spills from a main containment system, such as a storage tank. Any liquid that escapes the primary containment is held in the bund and prevented from overflowing onto the site or escaping to the atmosphere. A bund is made up of an impermeable floor and a collection of impermeable walls for a watertight area around a storage tank.Do I need a bund?

In short, the answer is yes. All hazardous liquid storage should have secondary containment because an uncontrolled spill could be catastrophic and cause environmental damage, creating a dangerous working atmosphere. Not only that, but you can face prosecution, unlimited fines and will be responsible for all clean-up costs under the polluter pays concept. There are some questions you need to ask yourself:- What kind of liquid is being stored? What are the ramifications for the environment? If you are storing liquids near bodies of water, for example, bunding is a must.

- How long will the liquids be stored for? Liquid storage containers can fail at any time, and the probability of failure increases as the container gets older.

- What is the approximate volume of liquid? Bunds can help avoid catastrophic containers spills, saving time and money in the clean-up process.

- Is your business ready to deal with the worst-case scenario? Spill kits, when used in conjunction with proper bunding, may provide peace of mind, as well EPA compliance.

- Control of Pollution (Oil Storage) (England) Regulations 2001

- Control of Pollution Act 1991

- COMAH Regulations 1999

- Control of Substance Hazardous to Health Regulations 2002

- Dangerous Substances and Explosive Atmosphere Regulations

Bund Specifications

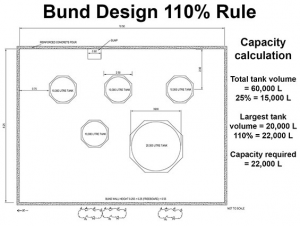

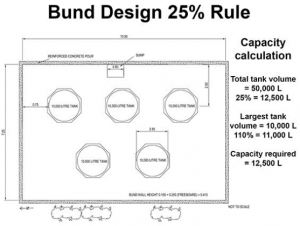

The industry standards are the 110% and 25% rules.

When only one container is contained within the bund, the 110% rule applies; in this case the equation is simple: the bund must have a capacity of at least 110% of the primary containment volume. For example, if a tank has a 10,000-litre capacity, the bund must have an 11,000-litre capacity.

When only one container is contained within the bund, the 110% rule applies; in this case the equation is simple: the bund must have a capacity of at least 110% of the primary containment volume. For example, if a tank has a 10,000-litre capacity, the bund must have an 11,000-litre capacity.

Bund Maintenance

Bunds that are not adequately maintained may develop failures which prevent them from functioning properly. Bund maintenance is an incredibly important aspect that is often ignored, as all infrastructure wears out over time and can become unfit for use if not properly maintained. Maintaining a proper maintenance and inspection schedule will help prolong the life of your bunds by allowing any required repairs to be completed in a timely manner, preventing the damage from worsening. Regular inspections Bunds must be inspected on a regular basis to ensure their integrity, imperviousness to liquid contents, and effectiveness as a part of the PIRP.- Rainwater Removal - Bunds that work well can collect and store everything that comes within them, including not just the liquid they are meant to catch, but also unnecessary material like rainwater. If a bund is not properly managed, unwanted build-up will reduce its capacity and cause it to fall short of the capacity requirements.

- Bund Surveys - Periodic inspections of the bund walls, floor, any penetration seals, and bund linings should be carried out in addition to routine rainwater removal. If any faults are discovered, they should be corrected as soon as possible to prevent the problems from worsening. Even hairline fractures can allow liquids to escape the bund, and structural flaws can greatly undermine the bund walls, potentially leading to failure in the event of a volatile load.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers