Secondary containment can come in many different forms, it is typically used on-site as a second line of defence in the event of the primary container of a hazardous substance failing. It is intended to prevent, control or mitigate major hazards.

Accidents happen - having the right spill containment means that an unpleasant surprise won’t turn into an expensive one. We're going to outline some of the most common types of secondary containment and when & where you need to use them.

Who needs secondary containment??

It is a legal requirement in the UK to have adequate secondary containment on all external oil storage over 200 litres. The Control of Pollution (oil storage) (England) Regulations 2001 explains the position in England, and there is broadly similar legislation in Wales, Scotland and Northern Ireland.

It is also highly recommended that you have secondary containment on all hazardous substance storage as their uncontrolled release may result in environmental damage and create an unsafe working environment.

Dangerous materials such as oils, solvents and chemicals can present a threat to soil, ground water, surface water - they can also pose a serious threat to human safety. In the event of a leak or failure of the primary storage vessel, secondary containment systems can prevent costly damage to equipment and physical risk to employees and nearby residents.

What are the main types of secondary containment?

Bunds

Bunds are generally used around storage tanks or drum storage areas where flammable or toxic liquids are held. They are designed to prevent oil, fuel or chemicals from being released into the environment if the storage tank or barrels are damaged and leak or burst.

Types of secondary bunded containment

Bunded Spill Pallets are used to hold storage tanks or drums containing hazardous materials, designed with deep sumps and drainage interceptors to safely control any spills. They typically feature removable grids for easy cleaning and forklift recess for safe transportation.

Uncovered spill pallets may fill with rainwater and in the event of a container leak, oil and chemicals could escape. Covered spill pallets eliminate this risk and keep the content safe and secure.

ICB bunding is designed to capture a minimum of 1100 Litres of liquid in the event of an IBC failing. If an ICB is present on site that contains anything other than water it must either sit in a bunded area or be sited on a bund. They are well-suited for intermediate spill containment for bulk containers that are stored indoors or outdoors. Optional dispensing units allow for safe decanting of liquids.

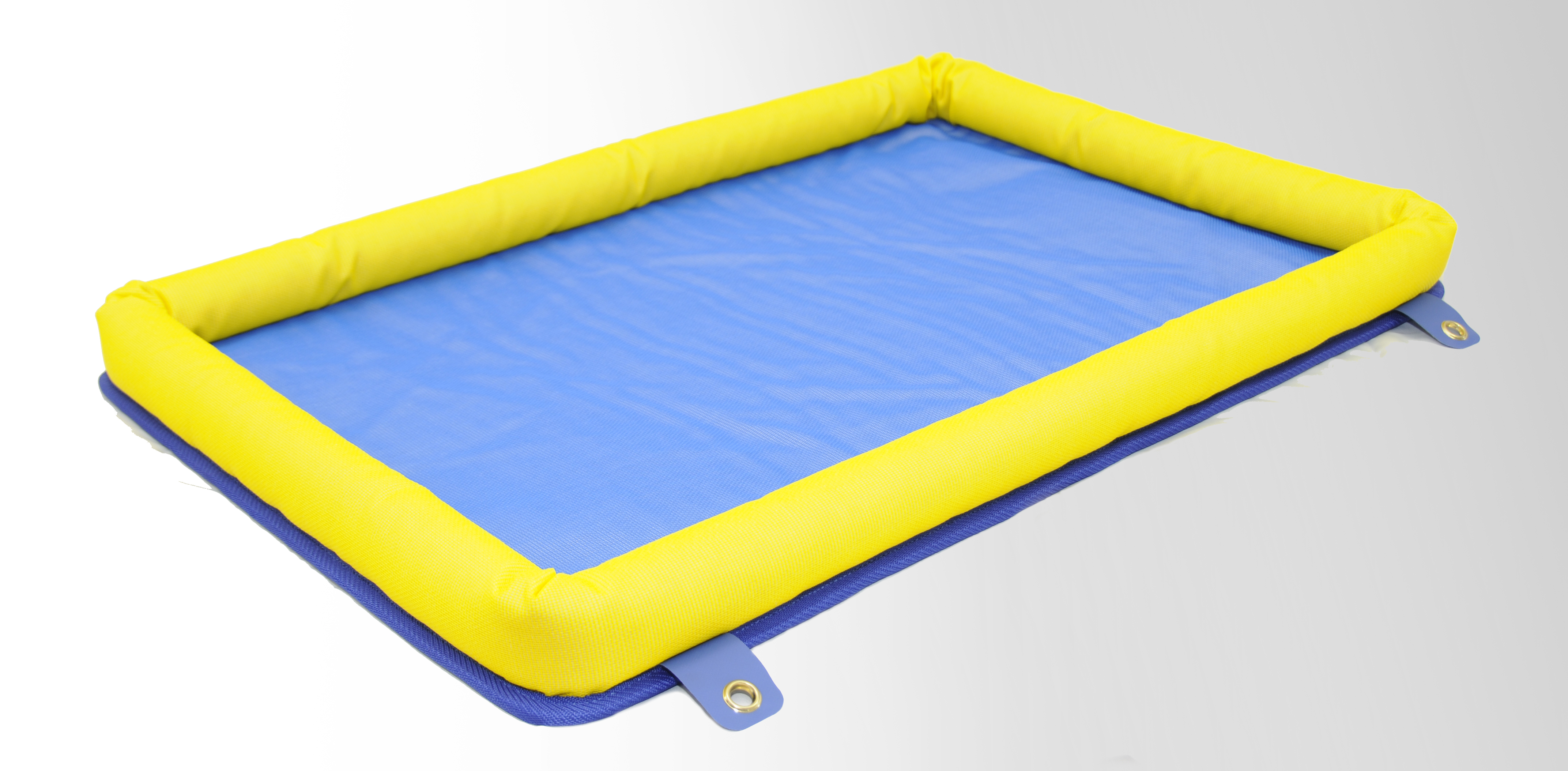

Portable bunds are great multi-purpose secondary containment systems that can easily be transported to catch fuel or chemical spills. They are an ideal solution where standard spill pallets are impractical due to practical storage and transport.

Portable bunds are useful for a range of applications, everything from bunding or oil tanks and drums to acting as a portable decontamination pool. Their simple assembly requires no special training or tools.

Plant nappies are both durable and lightweight, ideal for the control and containment of any leaks or drips that might come from industrial machinery or tools. It sits underneath the machinery or hand-held equipment to ensure that no oil or other hazardous liquids reach the ground, protecting the environment.

Plant nappy containment is best suited for use in outdoor areas especially in construction sites, particularly in rainy conditions.

Drip trays

Drip trays are often used beneath equipment that is liable to small leaks, such as pumps, or machinery- they are effectively mini-bunds that can be easily moved and stacked to be stored safely if they are not in use.

Where to use drip trays?

Drip trays are used to provide temporary storage for containers and drums. They are great for preventing drips and small leaks onto the ground. This makes them ideal for use under machines or cars, or in areas where small amounts of fuel or oil are needed. They come in a range of sizes and depths for different environments. We recommend lining with absorbent pads or rolls on top to make cleaning quicker and easier.

Types of drip trays

Benchtop trays made from galvanised steel are extremely durable and provide an easy and efficient way of preventing spillages. They are designed to be placed on worktops/ benchtops to store or decant hazardous materials. These trays effectively catch any excess fluid in the case of a spill or leak allowing you to safely dispose or reuse it.

Drip trays with removable grids are the perfect solution for managing spills and hazardous substances whilst keeping stored items such as cans or containers such as paint oil, or solvents protected. The removable grid keeps the items that are stored above the sump clean and safe from any corrosion or damage that the liquid might cause.

Polypropylene spill trays are extremely robust - resistant to acids and alkalis making them perfect for capturing oils and most chemicals. They are great all-round multi-purpose trays, ideal for storing oily tools or messy parts. We would recommend using these trays in conjunction with cushions.

What is the right solution for you?

Each secondary containment system has its advantages and disadvantages depending on your specific needs. Choosing the wrong system may result in unplanned expenses or unnecessary maintenance.

If you need any help deciding what is the right option for you we’re here to help. Get in touch to discuss your storage needs with Hyde Park Environmental’s experts in spill control.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers