Hazardous substances are often dangerous if not stored or handled properly. Many businesses across all industries use these substances and should follow the COSHH (The Control of Substances Hazardous to Health) regulations to help protect employees and the environment.

If hazardous substances if not stored and handled properly they can pose health risks to staff, damage to equipment, environmental damage and in some cases financial loss to businesses.

Organisations must follow COSHH regulations and have the precautionary measures in place to create a safe and compliant workplace.

Carrying out risk assessments on your site is a legal requirement. All employers are legally mandated to carry out regular risk assessments for all workplace hazards under the Management of Health and Safety at Work Regulations (1999).

Once risk assessments are carried out it is vital that the business puts strict procedures in place to ensure that a leak and spill does not happen. However, organisations must be fully prepared for a leak or spill to occur and have an established spill control procedure, with trained individuals to follow the plan in the event of an accident.

Below are Hyde Park Environmental's simple steps on how to prevent spills in the workplace.

Stock the appropriate spill response equipment

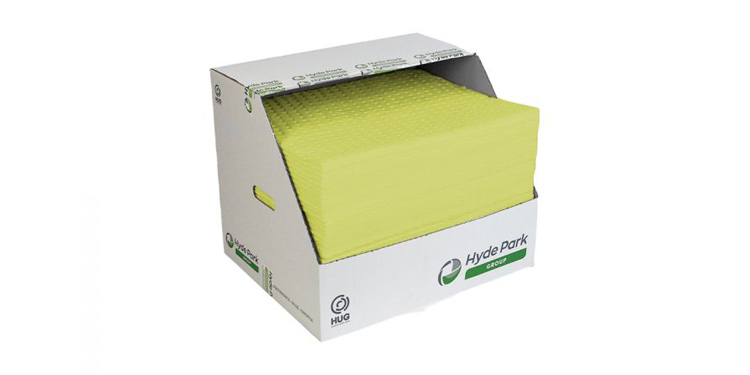

Spill control procedures are specific to each facility so the spill response equipment needed will vary between industries. However it is recommended that spill kits should be kept near places in the workplace where hazardous substances are stored or handled.

At Hyde Park Environmental our spill kits provide emergency response in the work environment, ensuring a quick response to every spill situation. Our maintenance spill kits, chemical spill kits, oil spill kits and speciality spill kits are highly visible, fully portable and are available in a range of different sizes. Each spill kit is packed with our high-quality HUG absorbent products, including socks, pads, absorbent pillows, and disposable bags for safe disposal of soiled absorbents.

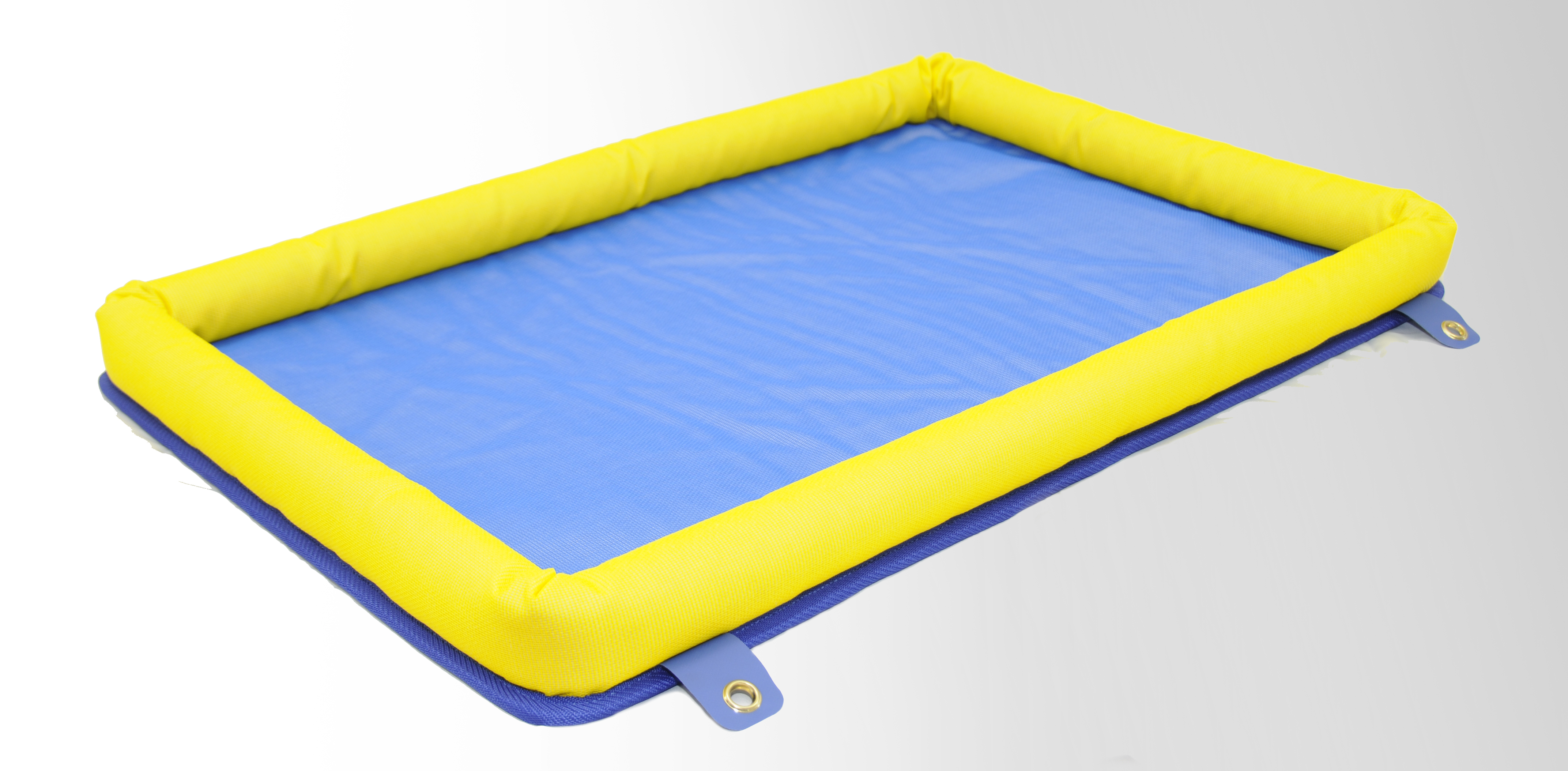

Bunds and spill pallets are used to capture and contain any spill. A detachable spill deck is often installed on spill pallets and bunds to protect the containers from being immersed in liquids.

Keep hazardous substances in covered areas

Hazardous substances should be stored in a designated area to ensure safety. Covered areas include bunded containment and storage.

It is important that hazardous substances should not be exposed to rainwater. Simply put, if a chemical spill comes into contact with rainwater it increases the volume of liquid that could potentially contaminate the workplace. An essential part of spill control is ensuring the area that a spill could occur is as small as possible. This keeps damage to a minimum and makes clean-up quicker & easier.

Therefore, hazardous substances should be housed in a location with a clear escape, and it is also recommended that the storage space is adjacent to washrooms. Substances should be stored in COSHH cabinets which should always be kept apart from other substances.

Avoid overcrowding in storage facilities

Chemical spills are readily caused by overcrowding of shelves with storage containers. Furthermore, keeping too many containers in one location makes it difficult to determine was substance is involved in a spill, and restricts access to the spill region for examination and clean up. Read our guide on how to store hazardous materials correctly to reduce the likelihood of spills in the workplace due to poor storage conditions.

Regularly inspect containers on site for leaks and deterioration

A chemical risk assessment is not a one-off exercise. It is important to inspect hazardous substance containers on a regular basis to ensure that there are no leaks and deterioration.

Inspections of containers should happen monthly, and businesses should pay particular attention to:

- Making sure the container’s exteriors are clean of spills and stains.

- Examining screw caps and closures for signs of wear and tear.

- Examining the containers for signs of degradation such as corrosion or bulges.

It is shocking how fast a chemical spill or leak can cause serious injury to staff and environmental damage. Ensuring risk assessments are carried out will provide the information needed to crate a robust emergency spill response strategy as well as well-established spill prevention practices to help to create a workplace where people and the environment are kept safe from harm.

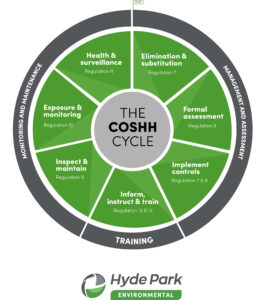

COSHH Cycle

The 'COSHH cycle' is the foundation on which all businesses are required to show compliance with the law.

Breach of these COSHH regulations by an employer or employees is a crime, punishable by an unlimited fine. Hyde Park Environmental can help you, to ensure this doesn't happen!

We're committed to helping to prevent spills in the workplace. Get in touch to dicuss your specific spill control needs with Hyde Park Environmentals experts in spill control.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers