When a spill occurs, emergency responders have to make rapid decisions and take immediate action so it is essential that they are properly protected from hazards and trained on various aspects of the Personal Protective Equipment (PPE) that they will wear.

PPE is designed to help keep you safe at work, particularly in hazardous environments. By wearing PPE you are minimising exposure to certain hazards, especially in workplaces that store and handle hazardous substances. Appropriate spill kits should be stored and used for the types of spills that may occur in any given area of the workplace. This means that your spill kit should be equipped with the right amount of absorbents, PPE and any other equipment that is needed to respond in an emergency.

Can I use the PPE in my spill kit for any spill?

If your spill kit is supplied with PPE you might assume that the PPE will function with the same sort of liquid as the absorbents in the spill kit. This is not necessarily true as many spill kits absorb a wide range of liquid and the type of PPE you need may differ depending on what kind of spill you are dealing with. As such, PPE is not usually supplied with spill kits as no single type of gloves, goggles or suit etc. is compatible with every chemical.

Some specialty spill kits are designed for specific spills such as Acid Neutralising Spill Kits. In this case, kits often do include PPE because the kit has a specific purpose, and is developed for the required chemical resistance.

It is best practice to add appropriate PPE to spill kits, or in a destinginated, clearly labelled area near the spill kit. Selecting the right PPE to add to a spill kit, a workplace risk assessment is required. Firstly, you must establish what types of chemicals or hazardous substances you’re working with, then you will be able to identify the appropriate level of protective gear that is required.

Planning for hazardous materials incidents is vital and PPE should be considered in three distinct areas:

- Respiratory protective equipment (RPE) includes disposable and reusable masks, breathing apparatus and powered respirators to prevent exposure to harmful substances through inhalation and ingestion.

- Chemical protective clothing (CPC) - Comprises gloves, boots, suits that can prevent direct skin contact, penetration and contamination.

- Protection against other foreseeable hazards for example, fire, heat, cold or projectiles.

One system that can be adopted for use at facilities where dangerous substances above a certain quantity are kept is the HAZCHEM code.

What is the HAZCHEM code?

The HAZCHEM code, (also known as the emergency action code (EAC) is a system that was developed by the British Fire Service for use on vehicles transporting dangerous substances in bulk to provide immediate action advice when attending an incident. It was then adopted by storage facilities that handle dangerous substances over a certain quantity.

The HAZCHEM code provides advice on 3 things:

- The type of medium to be employed in combating a dangerous substances incident where product had escaped, been split or is involved in fire.

- Possible violent reaction and hazard posed to the local population.

- Type of personal protective equipment to be worn by persons combating the incident.

You can find more guidance on this topic here.

What factors determine what PPE is needed?

Seven basic factors will generally determine the level and type of protection required by responders:

- Fire – Is fire or a flammable atmosphere present? Most chemical protective clothing (CPC) should not be used in fire situations.

- Toxicity – Primarily via inhalation, but also consider ingestion or skin exposure.

- Corrosiveness – From weak or strong concentrations of acids or alkalis.

- Oxidation – Where there is a reaction with organic materials, producing heat and oxygen.

- Temperature – Where the substance is at an extreme of temperature, whether hot or cold.

- Biohazards – Biological substances that pose a threat. Including medical waste or samples of microorganisms, viruses or toxins.

- Radiation (ionising) – Whether involving an unsealed source or not.

Other factors to consider when selecting the most appropriate PPE are:

- Form (gas/vapour, liquid, solid)

- Concentration levels

- Quantity of product involved or potentially involved

- Likelihood of direct contact

- Type of hazardous material incident (fire, potential fire, leak or spillage)

- Limitations of personal protective equipment (PPE) on identified tasks

- Nature and extent of proposed actions

- Location within the environment (open air, enclosed compartment or structure)

- Weather conditions

- Potential decontamination strategy

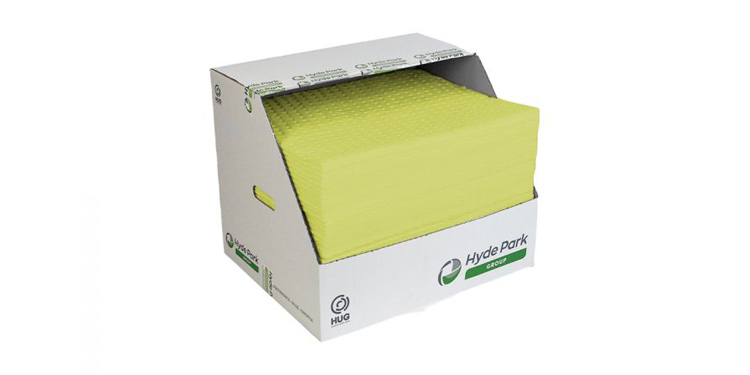

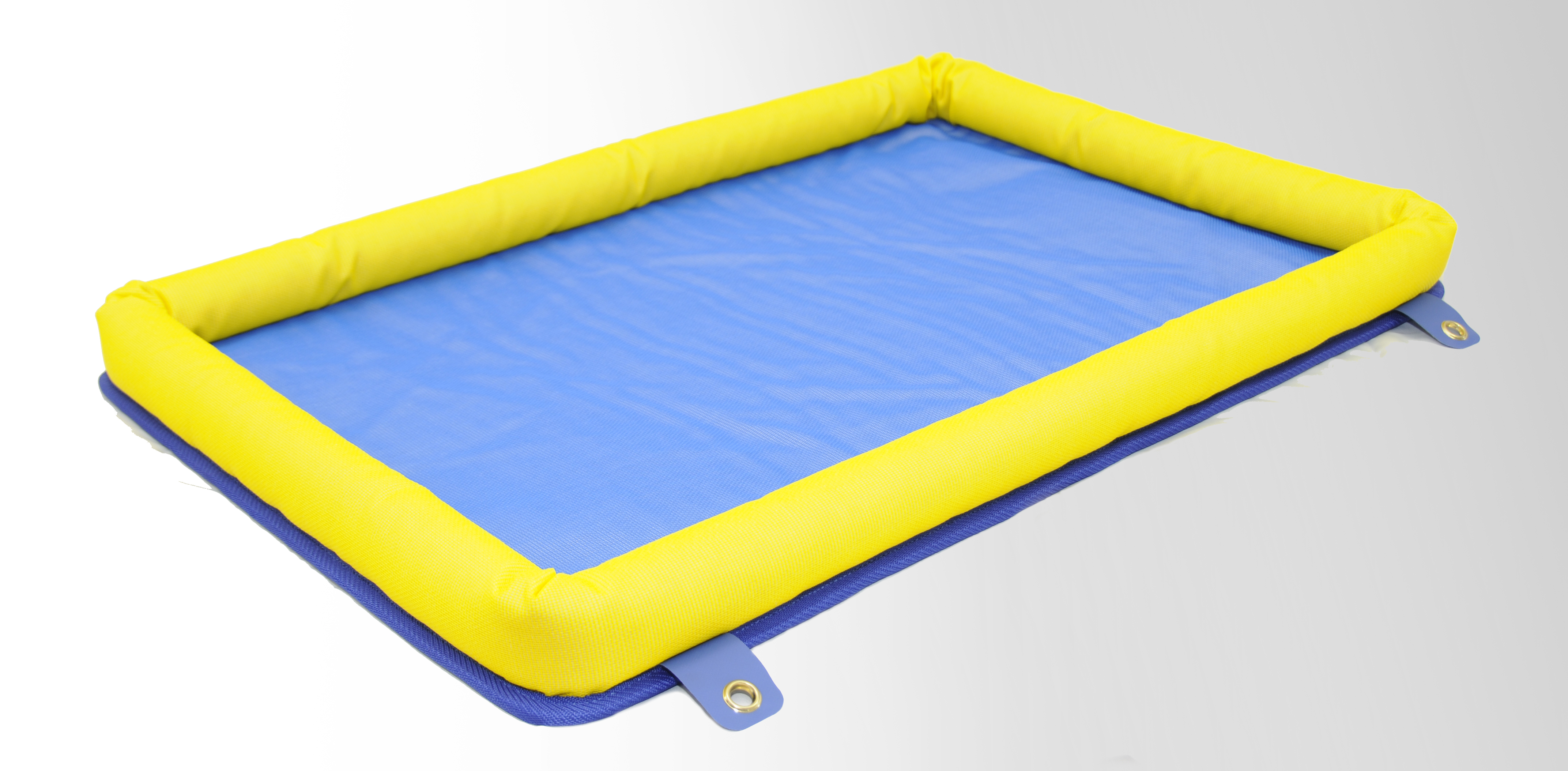

Oil Spill Kits PPE

This type of spill kit contains items designed to clean up oil, fuel, and other hydrocarbons. It contains special tools and other items that help to ensure that the spill does not spread such as disposable bags and absorbent pads. The PPE in these kits will need to be oil-resistant to clean up oil based spills.

Chemical Spill Kits PPE

This type of spill kit is perfect for cleaning up acids, caustic chemicals, solvents and aggressive liquids. It contains equipment to contain, clean and dispose of the spill. The PPE required for a chemical spill kit usually includes chemical splash goggles, gloves, apron or lab coat. Areas that have a high splash potential require a face shield and protective clothing be worn.

We’re here to help

Need more assistance or advice on the type of PPE you need? Get in touch with our spill experts to discuss your needs to develop the perfect spill solution for your unique business.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers