It is a legal requirement in the UK to have adequate secondary containment and spill control in place. Currently the Control of Pollution (Storage) Regulations (2001) apply in England, and there is broadly similar legislation in Scotland, Wales and Northern Ireland.

Do the regulations apply to you?

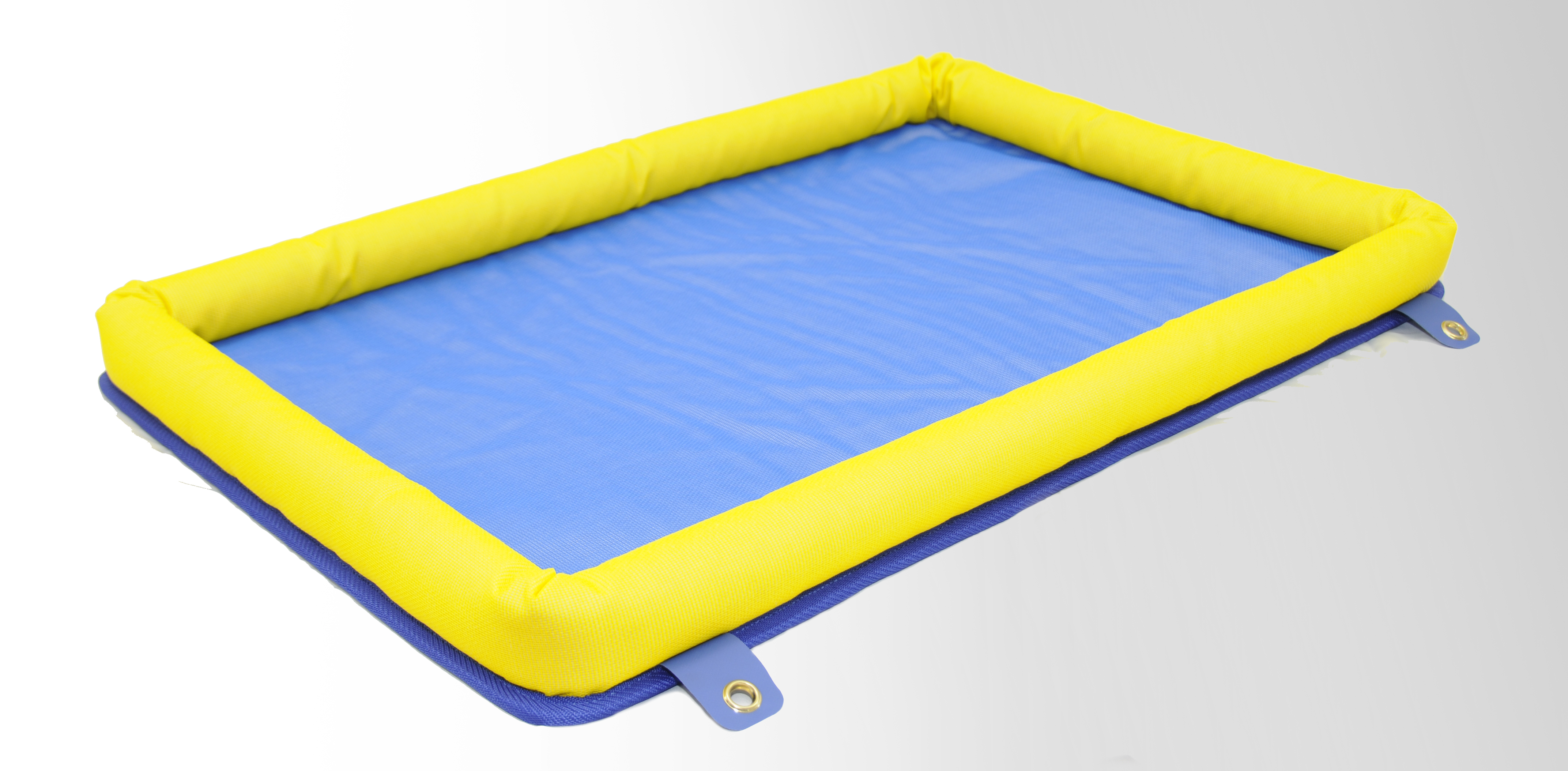

Dangerous materials such as oils, solvents and chemicals can present a threat to soil, ground water, surface water - they can also pose a serious threat to human safety. In the event of a leak or failure of the primary storage vessel, secondary containment systems can prevent costly damage to equipment and physical risk to employees and nearby residents.

To ensure you are compliant we've pulled together the laws, regulations & guidance for each area of the UK.

England

If you store oil in England you should check the DEFRA/ Environmental agency website for more information: DEFRA / Environment Agency

Here are some of the general oil storage and oil spill regulations that need to be complied with if you store 200 litres or more of oil aboveground (part of The Control of Pollution (Oil Storage) Regulations (2001))

- All oil containers must be sufficiently bunded

- The bund must hold 110% of the capacity of the largest container or;

- 25% of the total volume of the largest containers whichever is the greater

- If a single drum is being used, a drip tray can be used which holds 25% of the capacity

- Any valve, filter, sight gauge or vent pipe must be situated within the secondary containment (bund or drip tray)

- If a fill pipe is not within the secondary container, an additional drip tray must be attached under this.

Northern Ireland

If you store oil in Northern Ireland you should check the Northern Ireland Environment Agency (NIEA) website for details: NIEA

- The container shall be situated within a secondary containment system which satisfies the following requirements-

- Shall have a capacity of not less than 110% of the container’s storage capacity or, if there is more than one container within the system, of not less than 110% of the largest container’s storage capacity or 25% of their aggregate storage capacity, whichever is the greater;

- it shall be positioned, or other steps shall be taken, so as to minimise any risk of damage by impact so far as is reasonably practicable;

- its base and walls shall be impermeable to liquid and oil;

its base and walls shall not be penetrated by any valve, pipe or other opening which is used for draining the system; and - if any fill pipe, or draw off pipe, penetrates its base or any of its walls, the junction of the pipe with the base or walls shall be adequately sealed to prevent oil escaping from the system.

- Where a fill pipe is not within the secondary containment system, a drip tray shall be used to catch any oil spilled when the container is being filled.

- Any valve, filter, sight gauge, vent pipe or other equipment ancillary to the container (other than a fill pipe or draw off pipe or a pump) shall be situated within the secondary containment system.

- Where any drum is used for the storage of oil in conjunction with a drip tray as the secondary containment system, it is sufficient if the tray has a capacity of not less than 25% of —

- the drum’s storage capacity; or

- if there is more than one drum used at the same time with the tray, the aggregate storage capacity of the drums.

Scotland

If you store oil in Scotland you should check the Scottish Environment Protection Agency (SEPA) website for details: SEPA

The main requirements are:

- The container must be strong enough to hold the oil without leaking or bursting.

- The container must be positioned to avoid damage as far as is reasonably practicable.

- A secondary containment system such as a bund or drip tray must be provided to catch any oil leaking from the container or its ancillary pipe work and equipment.

- The secondary containment system must have sufficient capacity to contain at least 110% of the maximum contents of the container. If more than one container is stored, the bund should be capable of storing at least 110% of the largest tank or 25% of the total storage capacity, whichever is the greater (in the case of drums the capability should be at least 25% of total storage capacity).

- Oil stored in mobile bowsers must also be bunded.

- Bund base and walls must be impermeable to water and oil and checked regularly for leaks.

- Any valve, filter, sight gauge, vent pipe or other ancillary equipment must be kept within the bund when not in use.

- Above-ground pipe work must be properly supported.

- Below-ground pipe work must be protected from physical damage and have adequate leak detection. If mechanical joints have to be used, they should be readily accessible for inspection.

Wales

If you store oil in Wales you should check the Welsh Government website for details: gov.wales

The Control of Pollution (Oil Storage) (Wales) Regulations have been in effect from 2016 – the change is that they now apply to all fuel containers in Wales that can hold over 200 litres of oil.

This means that all above-ground IBCs, mobile bowsers, tanks must:

- Be 110% bunded

- Have all ancillary equipment (e.g. valves, gauges etc) contained within the bund

- Be fitted with a lock which secures access when the tank isn’t in use

- Be fitted with an automatic overfill prevention device

What are the benefits to your business

Legal compliance – Ignorance is no defence under law, so you need to understand which laws apply to you and your activities. If businesses cause pollution or don’t comply with these regulations, actions may be taken against you. A spill of a substance capable of harming the environment could result in a criminal prosecution by the relevant regulator under various regimes, and it could also lead to nuisance or negligence claims from persons affected by the spill.

Manage risk – Prevention is better than cure. Businesses which manage their risks are better prepared to deal efficiently with problems that may arise. The right supplier with knowledge of the law and technical capability will be able to de-risk your business, giving you peace of mind that you are as prepared as you can be in the case of a spill.

Reduce costs and save money – If pollution is caused, pay out costs can be huge including the clean-up and higher insurance rates. Effective spill kits can prevent this. View our range of spill kits here.

Talk to our spill control experts

Get in touch to discuss your spill control and containment needs.

Price Match Promise

Price Match Promise Same Day Despatch

Same Day Despatch On Site Support

On Site Support Account Managers

Account Managers